Mining. It’s the big business of northern Manitoba – always has been and for the foreseeable future, always will be.

It is the driving force and economic engine that has produced the communities of Flin Flon, Thompson and Snow Lake (with acknowledgement to contributions to the industry by the communities of Sherridon, Lynn Lake, Leaf Rapids and Wabowden.)

All over the region, drill bits churn into base metal rock by numerous companies wanting “a piece of the action” to supply base-metal demands nationally and to offshore countries such as India and China.

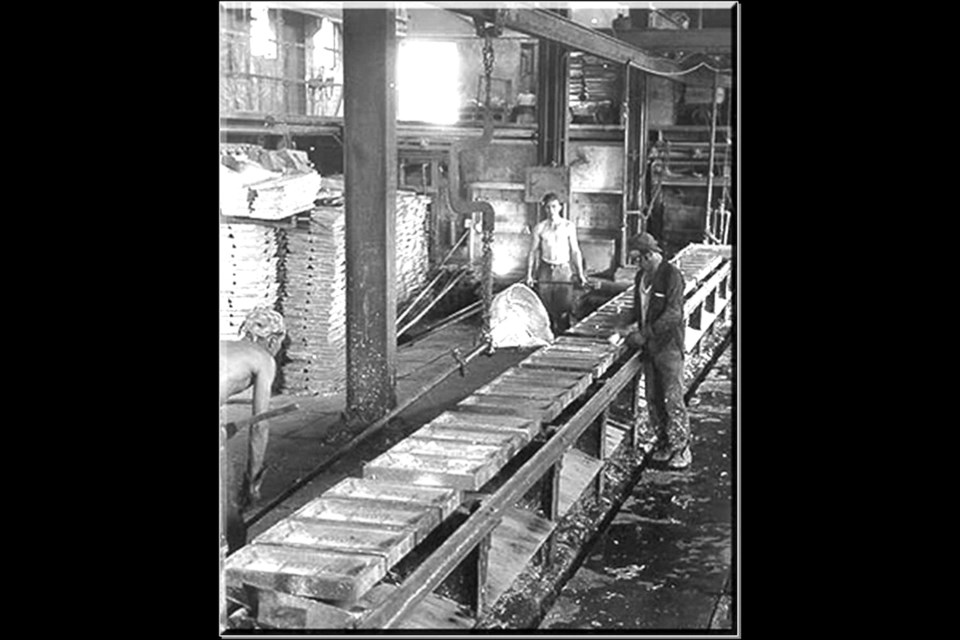

Modern-day mining involves the highest order of technology and equipment to bring new ore deposits on line. Jumbo drills and haulage machinery dwarf the people operating the equipment, and trucks and rail swiftly move the products off to market.

Of course things were not always this way. Mining has greatly evolved in our area over the last 100 years.

Mandy mine near present-day Flin Flon was discovered in 1915 and came on line as a the first producing copper mine in Manitoba in 1916.

Developed and mined by the Mandy Mine Company, a subsidiary of Tonapah Mining of Nevada, it still stands out as major triumph in mining circles.

Mandy was also the first mine to deploy a diamond drill in northern Manitoba,

blocking out an ore body with a value estimate of 25,000 tons of massive chalcopyrite containing 20 per cent copper with additional gold and silver.

Between 1916 and 1920, over 17,000 tons of ore were transported by horse and wagon to Sturgeon Landing for loading on barges, then over water to The Pas, and by rail to the smelter at Trail, BC. It was estimated at the time that for every $1,000 spent on diamond drilling, over $1.25 million of ore was discovered.

The importance of the diamond drill in the industry was a major step forward. As with most mines of the time, the Mandy ore body was close to surface, so a considerable tonnage was mined from surface before sinking shaft to 100 feet for stoping and then to 200 feet to allow mining from two levels.

By today’s standards this was a fairly crude and basic operation, as well as being very labour intensive. A similar operation took place at Herb Lake (near Snow Lake) with the Rex-Laguna mine opening in 1917 with the shaft being sunk by hand.

Mining in Canada was in its infancy but northern Manitoba was about to change that.

The famous and huge Flin Flon ore body was discovered in 1915 and came on line in 1929.

Elsewhere, INCO announced the sensational discovery of the Thompson ore body in 1956, which gave birth to the third-largest city in Manitoba, and HBM&S (now Hudbay) discovered the Chisel Lake mine in the spring of 1960, which led on to the opening of numerous mines in the Snow Lake area.

In the early 1900s drilling was revolutionized by the introduction of “lightweight” rock drills. The “jackhammer,” introduced by Ingersoll Rand in 1912 was a high point in the evolution of drilling equipment.

This handheld tool with automatic rotation was easier to handle and more efficient and reliable than earlier models. Nitroglycerine-based explosives were used for blasting, usually with electric caps. Mucking was by hand into relatively small buckets.

By the 1930s steam hoists were being replaced by a variety of single and double drum models, and the introduction of compressed air and electrical power into mines was a great step forward.

Mechanized rock drilling started during the industrial revolution for the specific purpose of drilling holes to insert explosives and break the muck into more manageable pieces.

Some mechanical drills were known as ”post drills,” which were mounted to large steel posts located at the face of the mine workings. These noisy machines, commonplace throughout the mining industry at the time, were known as “widowmakers” because water was very seldom used in the drilling process.

High concentrations of finely ground dust produced by these drills and poor ventilation were hazardous. Repeated breathing exposure led to a deadly condition known as “silicosis,” which took the lives of many underground workers.

The “Jackleg” and its counterpart stopper became common machines used in mining by about 1940, because they allowed for increased production that was unheard of at the time.

The machine was much lighter, more easily handled, and faster to set up and drill than any previous models. It could also be operated by a single miner.

During a period from about 1940 to 1980, literally hundreds of these machines were in operation daily at the huge main Flin Flon mine, and later at the Snow Lake mines.

Today there are many innovative procedures and equipment types “coming on board” the mining industry every year. All have the potential to make further dramatic changes to mining.

The industry that is the lifeblood of Thompson, Flin Flon, Snow Lake and other communities has changed dramatically since the Métis trapper and prospector David Collins led Tom Creighton to the outcropping of the gigantic Flin Flon ore body 100 years ago, and one can only speculate about future changes.

One thing is for sure, though: mining is here to stay. Happy 100th birthday.